Services

Our friendly and knowledgeable sales team offers no-obligation bottling consultations.

If you choose to work with us, you'll have a dedicated sales representative and support person, ensuring that all the pieces come together in a timely and stress-free manner.

We also offer custom repacking and custom mold design.

No Obligation

Bottling Consultation

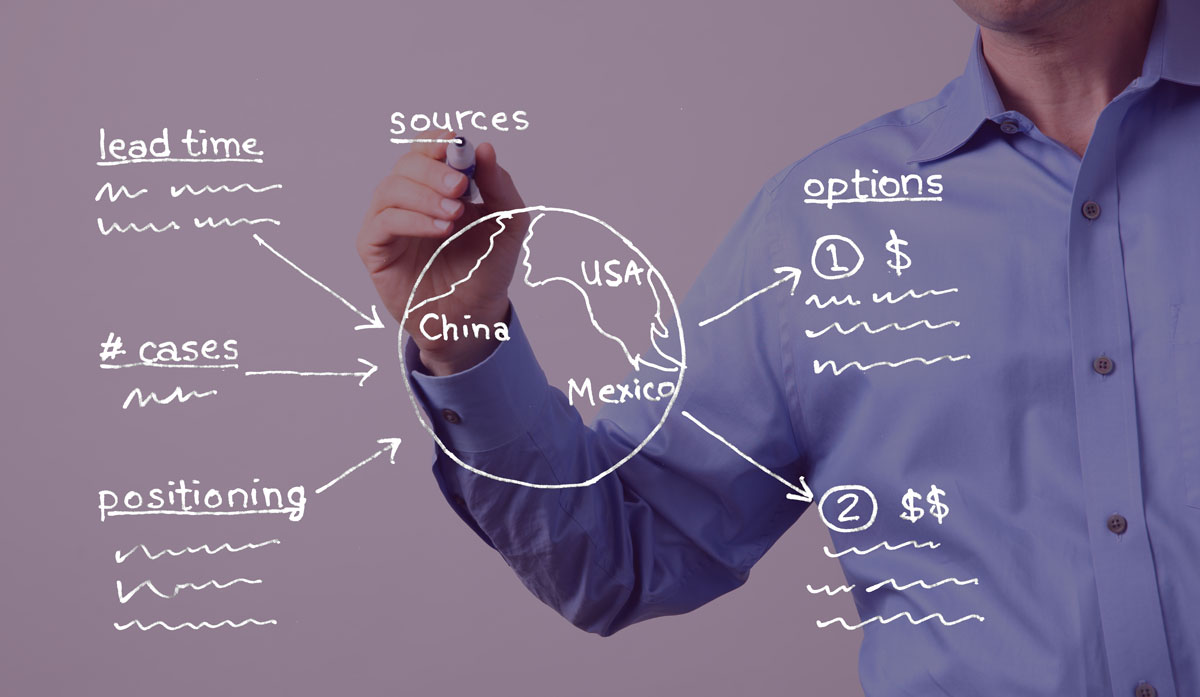

Our aim is to understand and serve your needs. In your bottling consultation, we'll discuss:

- Your existing stock of corks, capsules, closures or labels that you need to utilize.

- The varietals you’re bottling and what style you have in mind.

- Timeline and quantity (both short term and longer term needs, if any)

- Your plans for packaging: content vs custom printed box

- Together we'll consider some bottle possibilities. and if you're interested, we'll send or bring you samples to review.

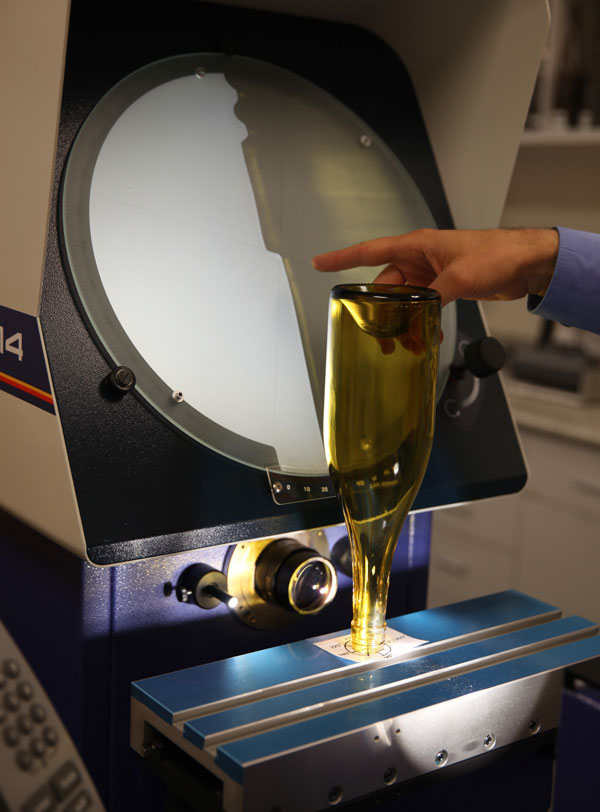

Need to match an existing bottle?

We have the equipment and know-how to make that happen.

Need to use up your stock of capsules?

We'll find you an appealing and compatible bottle.

Have an idea for custom bottle design or packaging?

We can help you explore options and secure pricing. If we can’t accomplish your vision at our manufacturing facility, we likely know a vendor who can.

Repacking

Receive your Bottles Ready-to-Fill

Automated repacking equipment simply can’t compare.

When needed, our team of steady hands will repack your glass from bulk pallets into cartons at our Fairfield headquarters or at the manufacturing facility. When in transit, our bulk glass is shipped with protective sleeves over every bottle to protect against scratches, scuffing or chipping. Even so, each bottle is efficiently inspected for:

- glass defects

- color imperfections

- chips and shards

- each lot is verified for dimensions and Prop 65 compliance.

Field Support

We'll Troubleshoot Your Bottling Operation

We know that bottling doesn't always go as planned. That’s why we always test capsules, closures and labels before ordering your bottles. But sometimes you might still need the on-site expertise of one of our seasoned field technicians. We'll even come out and help you with bottles you procured elsewhere.